Plastic-Free: Transitioning From Poly To Paper Packaging

by Sarah Quirk • Published January 25, 2022 • 29 minute read

Download a PDF of this guide here for easy reading and sharing.

As brands of all sizes set increasingly aggressive sustainability goals, many are exploring eliminating single-use plastic in their packaging.

Coalitions have formed in recent years to help entire industries minimize plastic packaging, including the Responsible Packaging Movement, various pacts driven by the Ellen MacArthur Foundation, the G7 Plastic Pact, and many more.

Over the past three years, EcoEnclose has developed an in-depth set of packaging options and resources to support brands adopting a plastic-free packaging strategy. When it comes to eCommerce, we have found that paper is the optimal material to turn to when seeking alternatives to poly-based packaging. Why?

Paper packaging can be curbside recycled, and this service is available to the vast majority of Americans. Paper as a material can also more readily utilize recycled content in its mix - easily made with 100% recycled content and high levels (up to 95%) of post-consumer waste - when created. This ease of recyclability and ability to contain high levels of recycled content make paper a highly circular material. Given this, we believe brands looking to eliminate plastic must not just opt for any paper alternative. They must seek out recycled (ideally 100% recycled with high levels of post-consumer waste) paper-based packaging to ensure that their commitment to going plastic-free is beneficial to the planet.

We have gained in-depth expertise in the many complex aspects of swapping plastic with paper. It is not as easy as simply ordering paper mailers instead of poly mailers and calling the strategy done. There are many considerations to keep in mind. Managing cost increases, seeking the correct paper mailer sizes, ensuring you have ample storage space, understanding and minimizing damage rates, training your operations and fulfillment team, and messaging to your customers, to name just a few.

We are well-positioned to be your plastic-free packaging partner and EcoAlly! You are considering or have already committed to switching to plastic-free packaging or more paper packaging in your DTC shipments. This guide will help you successfully navigate the transition process so your plastic-free packaging strategy can be a win for your brand, your customers, and the planet. Throughout this piece, we will help you understand when and how to engage EcoEnclose to help make this transition a success.

What This Guide Includes:

There are several moving parts when transitioning to a plastic-free packaging strategy, and we hope this guide assists you in the process! Below is a general outline of a plastic-free transition process and the contents of this guide.

-

Understand if a plastic-free strategy is right for you and your business.

-

Pick the correct new packaging. Choose the best sizes, material, and customization options and ensure it is more sustainable than your existing plastic packaging.

-

Implement the new packaging successfully into your fulfillment processes.

-

Communicate your new packaging choices to your customers: through custom branding, marketing avenues, and above all else- transparent language.

-

Understand common greenwashing examples and packaging to avoid.

Is Plastic-Free Right for Your Business?

This first question is where we always recommend starting. While paper packaging is increasingly popular and applicable, it is not the best option for every use case or company, and it is not necessarily the most objectively sustainable option.

-

Sustainability: 100% recycled poly packaging will almost always have a lower (often significantly so) carbon footprint than a 100% recycled paper alternative. Paper packaging wins on circularity and does not contribute to ocean plastic pollution, which are two issues that form the core sustainability goals of many brands. However, it has a more negative impact on climate change - arguably the most pressing environmental issue facing the world today. Given this, ask yourself if eliminating plastic is the right step for your business. Will this strategy meet your sustainability vision and goals? Or, are your main sustainability goals around lowering GHG emissions, in which case swapping out plastic will lead to an increase in your carbon footprint?

-

Functionality: Do your products require completely waterproof packaging? If so, non-plastic packaging is unlikely to provide this level of protection. It is important to note that paper mailers and corrugated shipping boxes offer a very high level of weather protection! We have shipped millions of paper-based packaging solutions to companies over the last 12 months, and we never hear from our brands that their paper packaging leads to rain or water damage! However, paper is not 100% waterproof. As such, brands who require this high level of protection will not find it in any non-plastic material.

-

Cost: Plastic is significantly less expensive to buy, ship, and store than plastic-free alternatives. Is the lowest cost possible the most pressing factor in sourcing your packaging? Can you afford a cost increase?

If you have considered these points already or have considered them and continue to be committed to plastic-free packaging - excellent! Read on for guidance on how to navigate the transition smoothly.

If these points give you pause and cause you to question whether or not plastic-free is right for your business, that is also fine. In this case, we recommend exploring multiple paths forward, including 100% recycled poly solutions, a combination of recycled poly and paper solutions, and the option of going fully plastic-free. Assess the pros, cons, and costs of all three paths before deciding how to proceed.

We have worked with quite a few brands that have started down this path only to end up with 100% recycled (50% post-consumer waste) poly mailers instead, or develop a dual strategy that includes some recycled poly and some recycled paper-based packaging.

Choose the Right Plastic-Free Packaging Alternatives

Audit your business to determine where single-use plastic currently exists in your packaging. For most eCommerce businesses, plastic can appear in the following:

- Primary shippers - poly mailers, poly bubble mailers, and any mailers made with a combination of plastic and other materials

- Internal or wholesale packaging - frequently poly bags

- Void fill - bubble wrap® and plastic air pillows

- Hangtags - often use plastic ties

- Packaging tape - sometimes made with plastic facestock

- Other packaging accessories - stickers, labels, etc

Once you have decided to go plastic-free, the next question is - what packaging do I use to replace my current plastic solutions?

In almost all cases, paper is the optimal replacement for plastic. Occasionally you will find that other natural fibers, such as hemp, may also be worth exploring; however, fibrous packaging (like hemp) is non-recyclable.

What should you look for in your paper-based alternatives to plastic?

Recycled Content is Preferred

It is a common fallacy to assume you have made a sound ecological choice by choosing paper packaging. Paper in the US is typically wood-based, and virgin paper comes directly from trees. These trees often come from ancient old-growth forests that are important carbon sinks and are essential to biodiversity preservation worldwide.

With this in mind, we have adopted guidance from Canopy Paper (Canopy’s Paper Steps) on what to look for in paper-based packaging. Specifically, source in the following order of priority:

-

Maximum Recycled, Post Consumer Waste Content: Our highest priority is the use of recycled content (specifically post-consumer waste*) in all of our products. Using recycled content wherever possible plays a major role in boosting and bolstering the circular economy.

-

Next Generation Fibers: These are natural fibers produced from agricultural waste instead of trees - think the remnants of wheat, flax, or hemp harvest. EcoEnclose offers a NextGen packaging paper made from 80% recycled content and 20% wheat straw paper. While these fibers are exciting and new to many marketplaces, remember to use next-gen fibers only when recycled content paper is unavailable or when the strength of virgin paper fiber is required. The top benefit of using next-gen fibers is creating a new use for what would otherwise be a waste stream in existing agricultural processes. We are careful to utilize this input only when we can confirm that its source is not expanding farmland to produce the crop (especially by clear-cutting forests). We also ensure the crop is not inherently degenerative to grow en masse. There are many non-wood fiber sources that we avoid using and increasing demand for, like bamboo, which is industrially farmed and requires large swaths of land and resources and can impact soil health negatively.

-

Virgin Paper Made with Certified Sustainable Trees: If, and only if, recycled content or responsible next-gen fiber inputs are not feasible for your solution, then make sure your virgin paper is from certified sources. Certifications help assure virgin paper is not coming from ancient and endangered forests, and the trees were grown in ways that are respectful of the environment. FSC® certification is preferred over SFI certification, but any certification is always preferred to none.

*A note on post-consumer waste (PCW) content:

PCW is our preferred source of recycled content and input source. However, utilizing PCW at high levels does come with a few structural considerations. As paper is continuously recycled, the fiber lengths of the original paper shorten with each repulping cycle. For this reason, 100% PCW paper is structurally weaker than 100% post-industrial recycled paper, or virgin paper, and is uncommon in the marketplace for paperboard or mailer production. For example, our paper mailer with the most PCW has 97% post-consumer recycled content and 3% post-industrial recycled content.

Choose the Right Paperboard Thickness

Most paper mailers are made with paperboard, a thicker paper material falling between standard copy paper and cardboard. Paperboard varies in thickness and measures in points (pt). You should choose your mailers based on the thickness of the paperboard needed to protect your products.

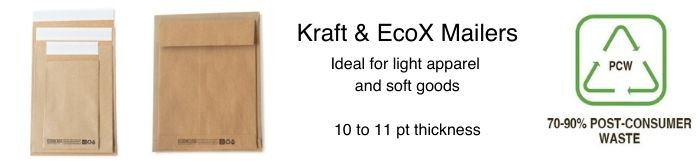

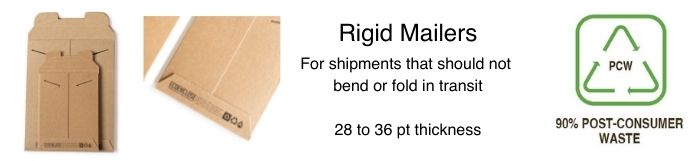

EcoEnclose offers a wide variety of paper mailers.

Shop Kraft and EcoX Mailers

Shop Apparel Mailers

Shop Rigid Mailers

Generally speaking, the paperboard thickness should increase as the size of the mailers increases. For example, a 6x9” mailer will perform well in a 10pt thickness, whereas a 19x24” mailer may be too large to use the same paper stock - and a 15 or 18pt paperboard would work best.

Most soft-goods shipments perform remarkably well in a standard 10 - 12pt paperboard mailer, but others (bulkier apparel) require a thicker paperboard to get the job done. Keep in mind that the thicker the paperboard, the more paper used, and thus, the higher the environmental impact. Balance this consideration against the mailers that work most successfully with your products.

Size Your Paper Alternatives Correctly

And train your team to select the right sizes for the right shipments.

-

Paper mailers can hold around 75% of the volume of the same poly mailer due to a difference in flexibility. If your plan to fully stuff your paper mailer, we recommend upsizing the size of paper mailers from their original poly mailer size.

-

When replacing very large poly mailers, you may need to substitute for a box or corrugated mailer to maintain structure versus a thinner paperboard mailer which works better for smaller shipments.

-

Work with your packaging provider to source samples of mailers in various sizes to see what works best for your products.

When Gussets are Needed

Gussets give a few inches of depth to a standard mailer by adding a folded strip of paper on the sides of the mailer, thus increasing the capacity inside a standard mailer. We offer gussets on several of our paper mailers and find they are most effective when used for inherently bulkier shipments like a sweatshirt or which holds multiple pieces of apparel or soft goods - instead of standard, mostly-flat shipments.

-

Every shipment may not require gussets. Use flat mailers whenever possible and gusseted mailers for shipments with multiple products or bulky apparel.

-

Gussets do not mean the shipment will be inherently safer in transit. When gusseted millers are under-packed, their corners and creases are potential places for stress to be absorbed and may impact the structure of the mailer.

-

Gussets typically increase the cost of a mailer.

Customization Beyond Stock Features

Size, gussets, material substrate, and glue zones are adjustable on paper mailers. Work with EcoEnclose to learn what options you have, and apply attributes that have been successful for your team to your new paper mailers. Contact Us.

Reusable Packaging

Some businesses are exploring the potential of transitioning away from single-use packaging in their DTC shipments to a reusable (often plastic) packaging option instead. We see reusable packaging as an excellent and sustainable solution for brands that rely on customer returns from a vast majority (or all) shipments.

Examples include: Rent the Runway (who ships clothing to be worn and returned), Nadine West (who ships clothing to be tried on, a portion of which is returned), and any company that accepts used apparel as a trade for store credit.

If this describes your business and you are curious about reusable packaging, get in touch at hello@ecoenclose.com. We work with brands to (1) assess whether or not reusable packaging makes environmental sense for their business model; (2) design and produce the right reusable packaging solutions given their specifications and ecological goals, and then (3) manage and track the results of their reusable packaging strategy to ensure it is meeting their operational and sustainability goals.

While we are very excited about these emerging reusable options, we do not necessarily see them as the best ecological option in many situations. Research published in 2021 from Fashion For Good shows how thoughtful we need to be here.

For example, measuring impact by carbon emissions, a reusable package will be less sustainable (even if returned 100% of the time) than a 100% recycled poly mailer used twice. The material and carbon footprint to create a reusable mailer - like a polyester - is significantly higher than the footprint to make a single or double-use disposable mailer. Coupled with the footprint of shipping that mailer back and forth, this means if the reusable mailers are not returned 95%+ of the time their overall footprint and the plastic waste they generate is larger than that of single or double-use packaging

Again, if this is something you are curious about, reach out to us! EcoEnclose will help in reusables, producing paper mailers, or both that will meet your goals around plastic-free, reuse, and recyclability.

A Note on Water Resistance

Brands often cite concerns around the lack of water-resistance of a paper mailer. However, we have found this to be statistically insignificant. Our customers have collectively transitioned millions of mailers from poly to paper even though paper mailers are not waterproof. We have not found water damage rates to spike significantly in this transition.

For those extremely concerned about water resistance, we would direct you to 100% recycled poly mailers (which include 50% post-consumer-waste) that are significantly more carbon-efficient than paper and align with EcoEnclose’s sustainability framework.

Order and Test Samples

Work with EcoEnclose to source paper mailer and internal packaging samples while you research. Our samples help determine the required sizing, design and structure, and material thickness for your packaging needs.

Cost Concerns for Sustainable Packaging

Cost is an important consideration whether you are focused on recycled paper packaging only or are moving to recycled poly mailers as part of your sustainable packaging strategy.

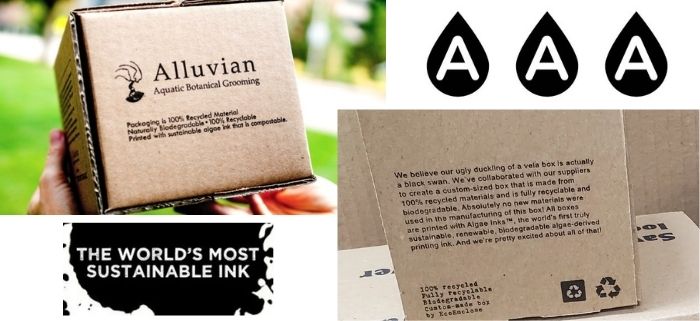

Paper is more costly a material to produce than plastic. Asia-made, non-traceable packaging is typically designed to be as cheap as possible. Maximized recycled content, manufactured in the USA at plants that pay fair wages, and built-in sustainability features (like a second seal strip for returns or printing with algae ink) commonly lead to a higher cost structure. That said, EcoEnclose has worked hard to establish list pricing in line with standard market options (such as options from Uline). Many of our enterprise clients have expressed that our higher volume options and pricing is very much in line with non-sustainable alternatives they had previously used.

Survey after survey has confirmed that eCommerce customers, particularly those shopping with conscious brands, care deeply about the sustainability of the packaging they receive and feel that these attributes will make them more likely to refer a friend and reorder. Brands are aware of this and are generally willing to pay a small premium for truly ecological packaging that represents and reinforces their brand values.

Prep Your Operation For The Poly to Paper Transition

Paper behaves differently than poly across many different dimensions. With this in mind, you need to prepare your procurement, warehouse, and fulfillment teams ahead of your transition from poly to paper packaging to ensure this is a success.

If you work with a 3PL to fulfill your orders, forward this guide to them, or better yet, share with them our Guide for Moving your Fulfillment Center to a Sustainable Packaging Strategy.

Increasing Storage Space (or Decreasing Order Volume)

Paper products typically take up more space than poly equivalents - especially for mailers. Expect to need more storage space for the same amount of paper mailers than you would need for poly mailers.

-

For example, a 10x13” mailer is packed:

-

250 units/case for paper

-

1000 units/case for poly

Building in Supply Chain Redundancy

Paper demand is at an all-time high right now, as many companies transition from poly to paper. We anticipate that supply chains will remain volatile as shocks ripple through the commodity markets and economy.

When you work with EcoEnclose for your paper packaging strategy, we will work with you to understand your requirements and build redundancy and slack into your paper packaging manufacturing. If you are not working with us, find other ways to build redundancy and excess capacity.

Shorter Inventory Turns for Packaging

Some brands will buy more than one year of their poly packaging needs at a time to manage supply chain risks, reduce unit costs, or both. We recommend purchasing so that you are holding six months or less of your paper packaging needs at any one time because paper has a shorter shelf-life than poly products, particularly in extreme temperatures or humidity.

Training Your Fulfillment Team to Work With Paper

Build in a training program for your fulfillment team, as adjusting to new material will require a learning curve for your team. Some key differences between paper and poly include the following.

-

Handle paper packaging with care as the material is more rigid and delicate. Paper packaging can tear and puncture more easily than poly counterparts. As such, your team members need to handle them more carefully.

-

Fill paper mailers to less capacity than poly mailers. If you typically stock a few sizes of poly mailers and ask your team to select sizes based on the dimensions of each shipment, you will want to train them to choose a slightly larger size of paper mailer than they would have had they been working with poly mailers.

-

Seal paper mailers with more pressure and time to ensure a strong adhesive bond to keep the package from opening during transit.

-

Paper requires more pressure applied to the sealing adhesive strip than poly-based materials. Apply pressure for a few seconds longer to ensure the adhesive of the mailer has cured (this is especially true for recycled paper surfaces, which have shorter and fuzzier fibers than virgin paper). Missing this step can cause paper mailers to open during transit leading to returns, damages, missing shipments, and products.

-

In addition to the added time and pressure needed to seal the mailer closed, expect to give equal attention to the adherence of the shipping label. Recycled paper fibers are shorter and more textured than virgin paper or poly, and it may require a stronger adhesive or more pressure to get a firm stick on the shipping label. We offer a High-Tack DT shipping labelwith a hot melt, industrial-strength adhesive. These are ideal for paper mailers with adherence issues with standard shipping labels.

-

Paper void fill and hangtags typically require more time than automated poly alternatives. For example, many brands swap poly void fill pillows with paper-based GreenWrap. While we love this switch, understand that fulfilling with GreenWrap is more time-intensive than pillow machines. We can help you transition from an automated air pillow void fill to an automated paper pillow option when working at high volumes.

Conducting Ship Testing

We recommend ship testing as the best way to assure performance once a new packaging product is introduced (or considered) for your products. Ship tests are a small set of sample shipments that utilize the new packaging, shipped to people who can give you good feedback on the packaging once it arrives. Many ship tests are sent to other company offices across the country, family, friends, and anyone who can provide detailed feedback or pictures of the packaging once delivered. Ship tests ensure new packaging fits your products well, protects them in shipment, and arrives in good condition.

We always recommend ship tests before you transition fully to a new packaging solution - this can save you the headache of purchasing large volumes of packaging that will not work for you!

For enterprise accounts (those who ship 500+ orders per week), we recommend trying a staggered ship test, starting at 1,000 units & then moving up in volume over a few increments, instead of starting with moving over your entire volume. If you choose to work with EcoEnclose on your enterprise-level plastic-free packaging strategy, we would love to help you execute these ship tests.

Transitioning Poly Components Over Time

Do not go full stop and transition every plastic packaging in your business in one month! Audit your business to identify where you incorporate single-use plastic and transition them one at a time. Even within a packaging category (such as mailers), transition your items one at a time.

For example, focus on your smaller mailers first, as smaller paper mailers tend to have a more 1:1 comparable performance to a poly mailer. Then, work your way up in mailer sizes over time.

Measuring Your Progress and Success

An important aspect to consider going into a plastic-free packaging strategy is - what does success look like for you? Specific questions may include:

- What environmental impact do you seek to achieve, and how will you measure it?

- What is your desired impact on customer experience and brand loyalty, and how will you measure it?

- What impact might plastic-free packaging have on your damage rates, and what level do you need to stay underneath?

This question of damage rates is particularly important. We recommend examining your current (pre-plastic free packaging) damage rates. Keep your Customer Service team listening for damage issues when you make this transition. Measure damage issue feedback against previous damage rates and ensure no significant increase.

It may be prudent to start with the most robust paper mailers (with higher paperweight - like 15pt - 18pt paperboard) and move to lightweight mailers slowly over time. Parallel testing can be a great way to get reliable data with consistent variables.

Have a period of overlap during your transition, and place survey prompts to draw feedback from customers. We recommend pursuing feedback using printed QR codes on mailers or after-shipment check-in emails.

Spotlight on Clear Poly Bag Alternatives

Find The Best Plastic-Free Internal Packaging

Poly bags post one of the most complex plastic-free packaging questions that apparel brands grapple with today.

These thin, clear plastic bags package individual garments at factories to cleanly ship them to distribution and fulfillment centers. Many fulfillment centers require that apparel is packed in these poly bags - for dust protection, easy picking and pulling, etc.

Unfortunately, single-use, clear virgin poly bags are an environmental challenge for many brands and a customer experience nightmare for brands with consumers who are vehemently against plastic bags.

Many brands, and industry associations, are reconsidering the clear poly bag. Brands have made more progress on testing and implementing innovative, eco-friendly alternatives to clear poly bags. For example,

Glassine (Paper) Bags: Glassine bags are translucent, thin paper bags that are curbside recyclable and naturally biodegradable. Many brands are considering these as a poly bag replacement. Glassine bags are harder to use and are not perfectly see-through. Notably, glassine bags do not (yet) include any recycled content.

Kraft Paper Bags: Some brands are going even further, using 100% recycled thin kraft bags (that are not translucent). If you can adjust your storage, picking and pulling, and labeling processes to allow for these paper-based solutions, it would set you apart.

Paper Roll Wrap Alternatives: Many brands we work with ditch the bag altogether and roll-wrap their garments which are then held together by raffia, hemp twine, or a paper EcoBand. While this strategy does expose more of the garment to dust, we believe 3PLs can develop a pick bay strategy that provides enough dust protection so that brands could feasibly utilize this type of solution.

Burrito Wrap: Similar to roll-wrapping, some brands use the same rolled shape of their apparel but use pliable packaging paper to wrap fully around the product like a burrito. These wraps seal with tape or a custom branded sticker. While this needs more time and material than using a hemp or raffia tie, it covers the entire product from dust or dirt and allows for an additional place to custom-brand and communicate to customers. Perhaps most importantly, it will stand out to your customers!

100% Recycled Clear Bags: If it does not make sense to adjust your operations for paper-based poly alternatives (or if the carbon benefits of poly make more sense for your ecological goals), move to 100% recycled clear poly bags instead. Maximize recycling of these bags by having your fulfillment teams remove your product from the bag before shipping and then thin-film recycling these bags en masse with a recycling partner (like EcoEnclose, EcoCycle, or your local hard-to-recycle stream.)

Communicating Your Sustainability Choices To Your Customers

Once you have decided to make the investment and transition to plastic-free packaging, make sure to get your marketing team involved! With the amount of time and effort put into this endeavor, and the thoughtful intention behind it, sharing the environmental factors and goals of your packaging tells your customer a holistic story about the ethos of your company.

Custom Printed Packaging

Is a great way to communicate:

- The sustainability attributes of your packaging and any sustainable add-ons.

- Examples: 100% Recycled Paper, 90% Post-Consumer Waste / Printed with algae ink / 100% recycled paper, made in the USA.

- The proper disposal instructions for the end-receiver.

- Examples: Curbside Recyclable / Please Recycle with Paper / Recycle in your single-stream blue bin or wherever paper is recycled!

- Your broader sustainability goals and transition to paper process.

- Example: This packaging may look a bit different than usual! Our 2022 goal is to make 90% of our packaging curbside recyclable, so we are using more and more paper products. Please share any feedback about your shipment and recycle this mailer wherever paper is accepted after you receive this package.

Avoid Greenwashing

To build trust with your consumers. To that end, be sure to:

-

Provide as much detail about the product and its production as possible, printed directly onto the packaging itself (since this is all the end consumer will see) and in any digital format.

-

Communicate sustainability attributes and disposal directions clearly, directly, and honestly on the packaging. Some of the examples of poor communication include:

- Recyclable (Where? How? With what?)

- **nondescript chasing arrows symbol**

- Recycled (how much recycled content?)

- 100% Recycled (how much is from post-consumer waste?)

- Eco-friendly (how?)

Communicate the Message

A huge part of elucidating the investment you have made in sustainable packaging is to market and communicate it to your customers and consumers. Focus on:

- Product inputs - recycled content % and post-consumer waste %

- Production location

- End-of-life / Disposal Directions

Take some time to review the custom printed packaging you currently use. Does it communicate how to dispose of it, what it is made of, or where it was produced? Does it use vague terminology like sustainable packaging or eco-friendly without qualifying or explaining how or why? Use these questions as a guide for how to improve future packaging communications.

You can communicate by custom-printing your packaging directly, and you can even print this in carbon-negative black Algae Ink with EcoEnclose!

Algae Ink is a revolutionary ink developed by Living Ink Technologies that utilizes algae cells for pigments, making it safer and cleaner to work with, and more compatible with the recycling and composting process. Black algae ink is available for all paper-based packaging. Learn More.

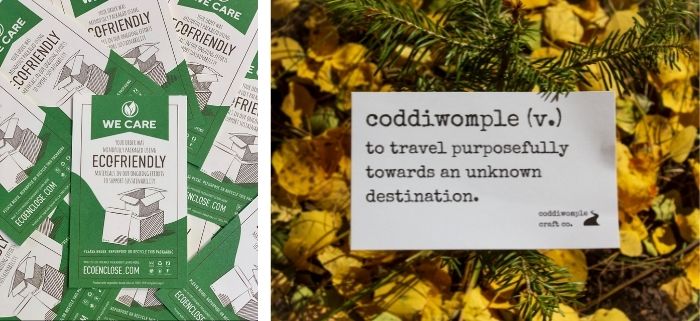

If custom-branding your packaging directly is not an option for you, you can still communicate your choices to your customers!

- Easily add a custom recycled notecard or a We Care Card to each shipment.

- Use your marketing channels - social media, on your site, or through order confirmation/shipping emails, etc. - to communicate your plastic-free choices.

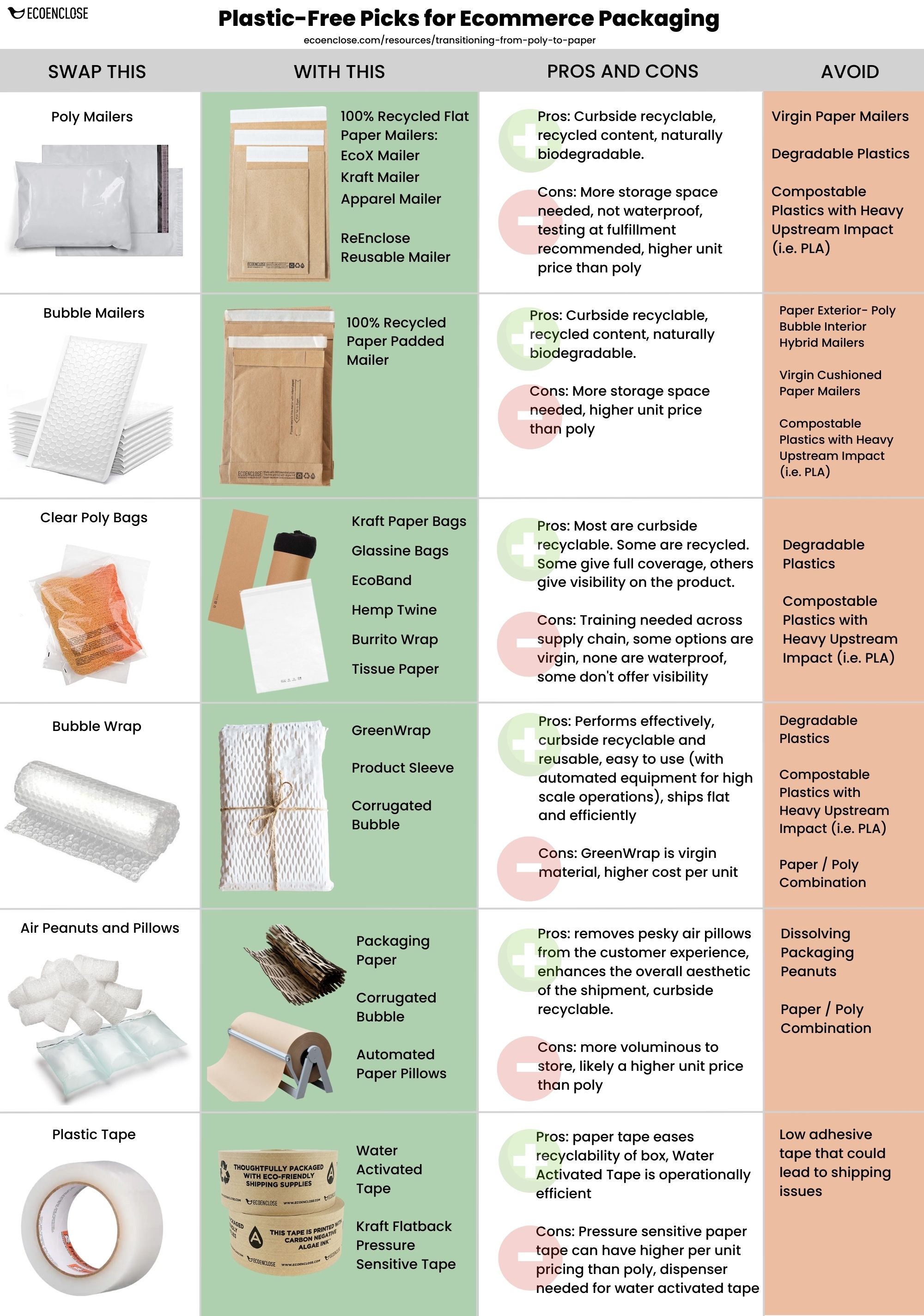

Our Picks for Plastic-Free Packaging

|

Plastic Packaging |

Plastic-Free Alternatives |

Pros & Cons |

Resources |

|

Poly Mailer |

Pros: Curbside recyclable, boosted circularity, naturally biodegradable. Cons: Higher per-unit costs, more storage space needed, not waterproof. |

||

|

Poly-Bubble Mailer |

|

Pros: Curbside recyclable, boosted circularity, naturally biodegradable. Cons: Higher per unit cost, typically heavier than poly bubble mailers, often need to size up from poly size. |

|

|

Clear Poly Bag |

|

Pros: When used with paper shipping packaging- paper internal packaging allows for the entire package to be curbside recycled, removes the pesky polybag, a unique approach gives you a chance to set yourself apart from others. Cons: More time and training adjustment needed for fulfillment, not dust-proof, lack of visibility of the actual SKU (for some options), ties, and wraps can be more challenging to scale to high volumes. |

|

|

Bubble Wrap® |

Pros: plastic-free wrapping option that performs as well as plastic wrapping, curbside recyclable and reusable, easy to use and scale to high volumes. Cons: higher per-unit costs (nothing beats the cost of poly bubble wrap®) |

||

|

Plastic Air Pillows |

Pros: removes those pesky air pillows from the customer experience, enhances the overall aesthetic of the shipment, curbside recyclable. Cons: more voluminous to store, higher per-unit costs. |

||

|

Plastic Tape |

|

Pros: paper tape on paper/cardboard allows for the entire package to be curbside recycled as is, potential to custom-brand with your logo or colors. Cons: higher per-unit costs than standard plastic pressure-sensitive tapes. |

|

|

Hang Tag Strings |

|

Pros: sets you apart from competitors with a more memorable material choice, twine, and safety pins can be reused. Cons: higher per-unit costs, may require training for your production and factory teams, potentially more time-consuming to apply to merchandise. |

Plastic Free Isn't Enough! Choose Responsible Natural Fibers |

|

Plastic Stretch Wrap |

Pros: a curbside recyclable and naturally biodegradable alternative to plastic stretch wrap, reusable as sustainable void fill Cons: works well for symmetrical, square pallets, but is not the best solution if your pallets are non-uniform and hold a variety of mixed items. |

Plastic-Free Solutions to Avoid

Skip the Bioplastic, especially the PLA!

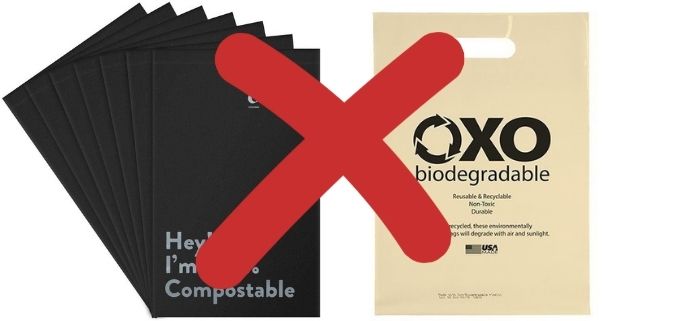

Bioplastic is an umbrella term for packaging either 1.) made from bio-based sources (like plants), or 2.) able to biodegrade (to industry standards) in a home or industrial compost environment, or both. Examples are PLA Shipping Mailers, PLA / Compostable Clear Poly Bags, PLA / Corn Starch Packing Peanuts, Oxo-biodegradable plastics, or plastics with biodegradable additives.

Bioplastics offer an incredible service for the packaging of naturally biodegradable or compostable products. However, we do not see their value when used in eCommerce packaging.

PLA is the most popular and cheapest bioplastic in the world today. It is made with industrial corn - a crop that wreaks havoc on waterways and soils and relies heavily on fossil fuels to produce. Additionally, only 4% of Americans have access to industrial compost streams or facilities in their locales, so this packaging is frequently incorrectly recycled (also known as wish-cycled) or landfilled - where it breaks down over time to create methane pollution.

Finally, even when Americans can compost their eCommerce packaging, their local composters do not want these low-value inputs that degrade their compost, making it more difficult to sell.

In conclusion, bioplastic mailers are a top contributor to greenwashing in eCommerce packaging.

Learn more in these resources:

- Don't Replace Plastic with Corn: Lessons from Ethanol

- We Could Sell You This Biodegradable Poly Mailer, But We Won't

- Quick Guide To Responsible Composting

- Compostable Does Not Mean Naturally Biodegradable

- Compostable Bioplastics Do Not Prevent Marine Plastic Pollution

Paper / Poly-Bubble Hybrid Mailers

There are mailers with both paper and poly components on the market. Some have a paper exterior encasing a poly-bubble liner. Others are mainly paper with expanded poly-foam to serve as cushioning.

These mailers are often marketed as sustainable, stating the paper is curbside recyclable and the poly component is removed from the recycling stream during the paper pulping process. While this is technically true, we have chosen not to offer these mailers given the knowledge that they 1.) still utilize plastic components in their creation and 2.) contribute to higher contamination levels in the paper recycling stream.

Fiberglass Mailer

Adding fiberglass reinforcement to paper products can add strength and prevent tearing and is most commonly seen in Reinforced Water-Activated Tape. This level of reinforcement is not needed for the vast majority of shipments in paper mailers and therefore is not a product we promote for widespread use in mailers. Fiberglass is another contaminant in the recycling process, adding more work and contamination to this stream. Eventually, the fiberglass is screened out and landfilled.

Virgin (Tree-Based) Paper

Choosing paper-based packaging over poly-based packaging does not automatically make paper-based packaging a sustainable choice.

In both the USA and abroad, virgin paper is typically tree-based. EcoEnclose’s vision is to design packaging as circular as possible - made from recycled packaging and able to be recycled into more packaging in its next life. At this point, you likely understand why using trees to make boxes and mailers is not something we agree with - regardless of certifications of those forests.

When making your decisions, use the hierarchy of Canopy’s Paper Steps to ensure you are using the best inputs to the highest extent possible, or reach out to us! We understand every company and shipment is different, and we love to help advise on these nuanced decisions.

Work With Us!

We always want to partner with conscious brands, and those navigating the nuance of transitioning to sustainable packaging throughout their supply chain. We would be thrilled to work with you. Contact us and learn more at:

hello@ecoenclose.com // 888-445-6575 // www.ecoenclose.com // @ecoenclose